Choosing the formwork

20 March 2025

Choosing the formwork: a guide for builders of the Republic of Uzbekistan and the city of Tashkent

The choice of formwork is an important stage in construction, which can significantly affect the quality and speed of work. A formwork is a temporary structure used to form and hold concrete elements until they harden and become strong enough. The right choice of formwork guarantees not only the strength and durability of structures, but also the optimization of labor and material costs. Let’s look at the main factors that need to be considered when choosing a formwork.

- Type of construction

The first step when choosing a formwork is to determine the type of structure that you plan to erect. Different designs require different types of formwork:

- Foundation work: Universal Alwood formwork systems are most often used for the construction of foundations. These systems provide the necessary strength and stability to support the concrete.

- Wall structures: For wall elements, you can choose Alwood linear large-panel formwork. This formwork ensures fast and high-quality installation.

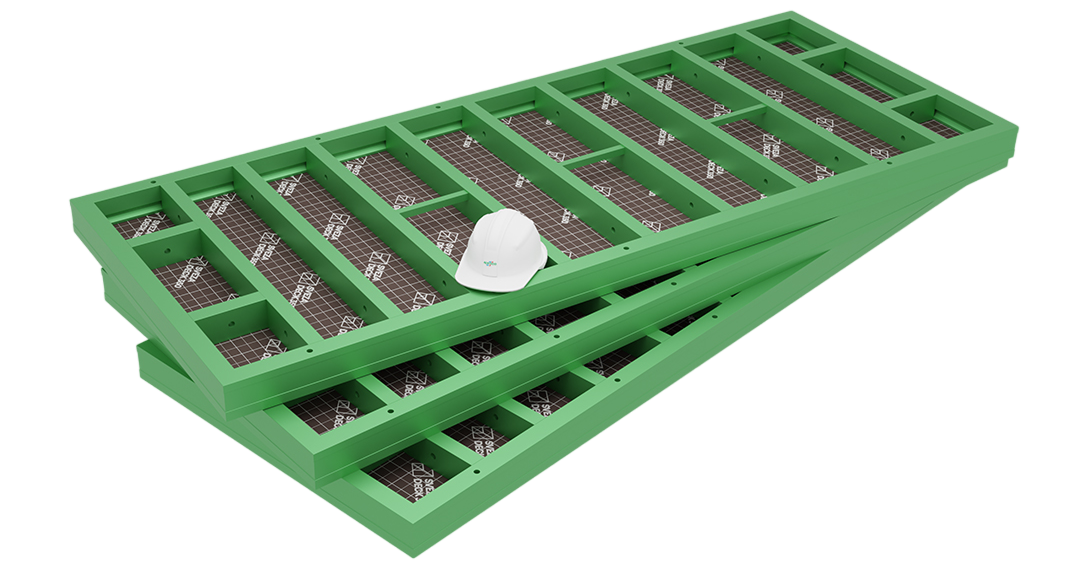

- Reinforced concrete floors: For horizontal surfaces such as floors, formwork systems are used, including telescopic racks, volumetric formwork, Alwood wooden I-beams and other structures. In this case, not only strength is important, but also ease of installation and disassembly, which is provided by the Alwood system.

- Formwork materials

The formwork can be made of metal, wood or plywood.:

- Wooden formwork: This is a traditional option that is suitable for small and uncomplicated objects. It is inexpensive, but requires more time for preparation and installation. It is also not durable and can be used a maximum of 5 times. In addition, the concrete surface is less even.

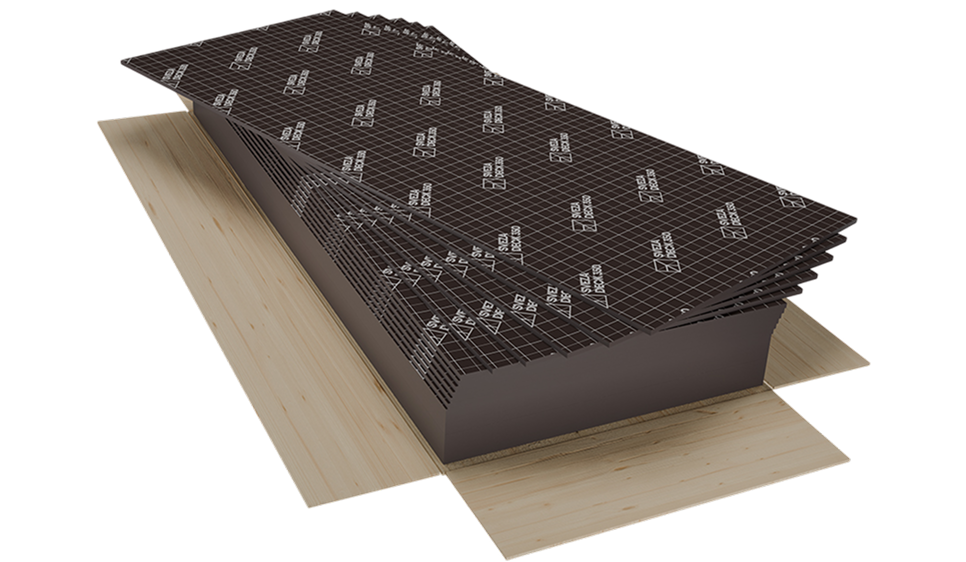

- Alwood Metal Formwork: It is made of high-quality metal. It is durable and resistant to mechanical damage, which makes it ideal for repeated use (up to 400 times) on large construction sites. Sveza plywood is also used for the deck, which is made from birch and has high performance characteristics.

- Plywood formwork: This type of formwork is similar to wooden formwork. The surface is smoother, but the labor costs for manufacturing and installation are similar to wooden formwork, which increases its cost.

- Design features

When choosing a formwork, it is important to take into account its structural characteristics.:

- Adjustability: Alwood formwork can be customized to various shapes and sizes of structures, which is especially important for complex and non-standard architectural solutions.

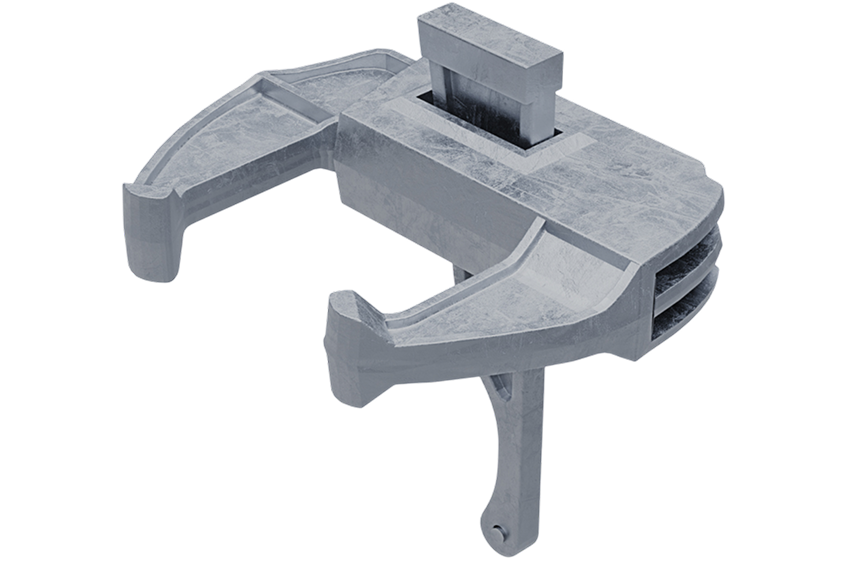

- Speed of installation and disassembly: The Alwood formwork system is easy and quick to install and dismantle, which helps to reduce construction time and reduce costs.

- Tightness: The Alwood formwork is sealed, which prevents concrete leakage and ensures a smooth surface.

- Operating conditions

The conditions in which the formwork will be used also play an important role.:

- Climatic conditions: In regions with high humidity or extreme temperatures, you may need a formwork that can withstand these conditions without loss of strength. The Alwood formwork is adapted to various climatic influences and is ideally suited for the conditions of Uzbekistan, as well as the CIS countries.

- Economic efficiency

When choosing a formwork, it is worth considering not only the initial costs, but also its economic efficiency in the long term. For example:

- Reuse: Alwood metal formwork, although more expensive at the start, can be used up to 400 times, which significantly reduces overall costs.

- Maintenance and care: It is important to consider the need for maintenance and repair of the formwork, as this also affects overall costs. The Alwood structure is very reliable and made of durable materials, which allows you to save on maintenance and repair, as it does not break or deform.

- Storage of the formwork: Alwood formwork does not require special storage conditions, while wooden and plywood formwork are susceptible to moisture and deformation.

Conclusion

Choosing the right formwork is not only a matter of convenience, but also the key to a successful construction project. Taking into account the type of construction, materials, design features, operating conditions and economic efficiency, you will be able to choose the optimal solution that will ensure the high quality and durability of the facilities under construction. Do not forget to consult with Alwood experts, who will help you take into account all the factors in order to make an informed decision and avoid unnecessary costs in the future.