Advantages of metal formwork

26 March 2025

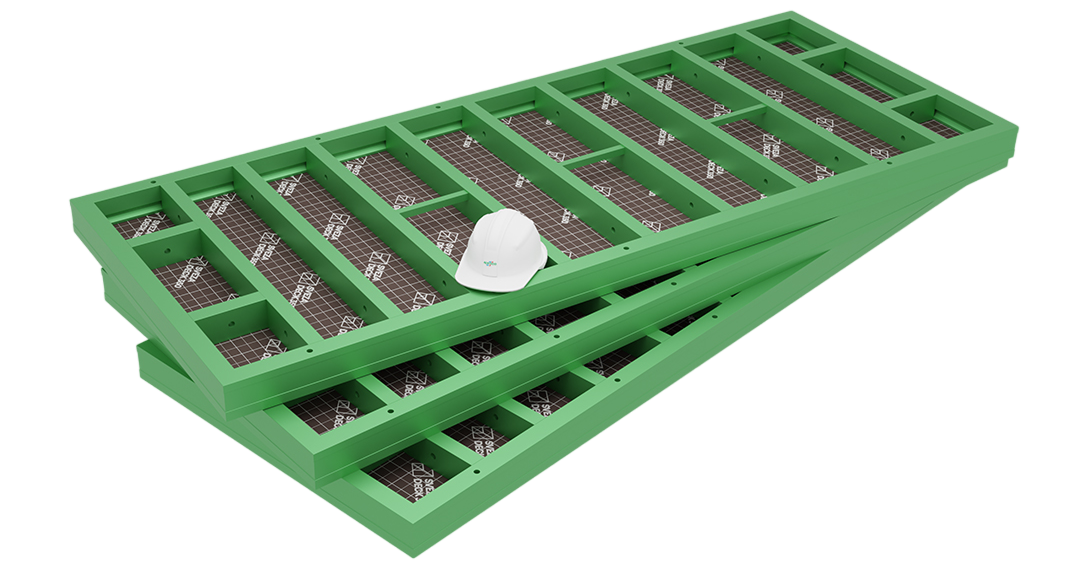

Advantages of Alwood metal formwork over wooden formwork

Formwork plays an important role in construction processes, ensuring the formation of concrete structures. For many years, wood has been the main material for making formwork, but modern technologies offer more effective solutions. Alwood metal formwork is an innovative product that surpasses traditional wooden systems. Let’s consider the main advantages of Alwood metal formwork in comparison with wooden formwork.

- Durability and wear resistance

Alwood Metal Formwork:

- It is made of high-quality metal, which has excellent corrosion resistance.

- The use of high-quality metals ensures a long service life, which significantly exceeds the service life of wooden formwork.

- Minimal repair and replacement costs due to its high wear resistance.

Wooden formwork:

- It is exposed to moisture, which can lead to rotting and deformation.

- It requires regular maintenance and replacement of individual components, which increases operating costs.

2. Easy and convenient to use

Alwood Metal Formwork:

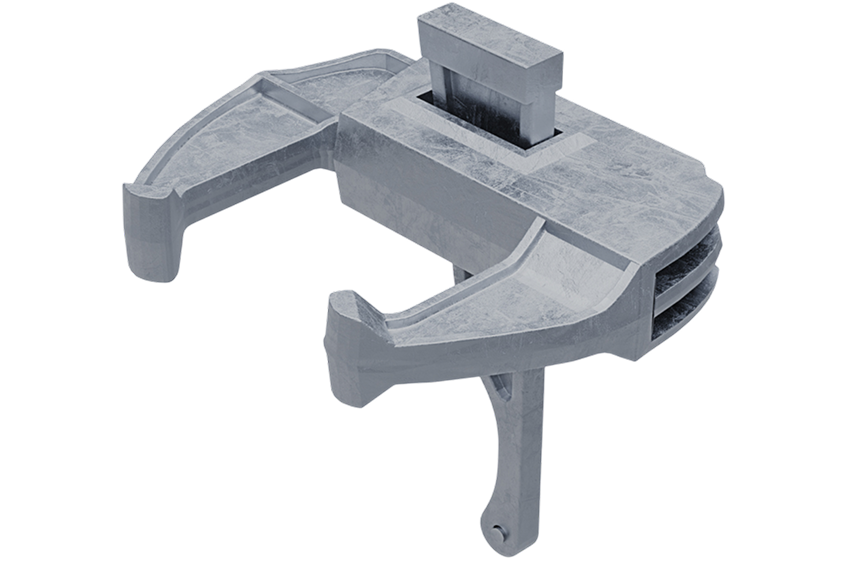

- Cast iron and metal elements make installation easier.

- The Alwood system is designed for quick and easy assembly, which reduces installation and disassembly time.

- Modern locking mechanisms and connections simplify the work with the formwork.

Wooden formwork:

- It is less convenient to operate.

- The assembly and disassembly process may take longer and require more workers.

3. Cost-effectiveness

Alwood Metal Formwork:

- The initial costs are justified by durability and reduced maintenance costs.

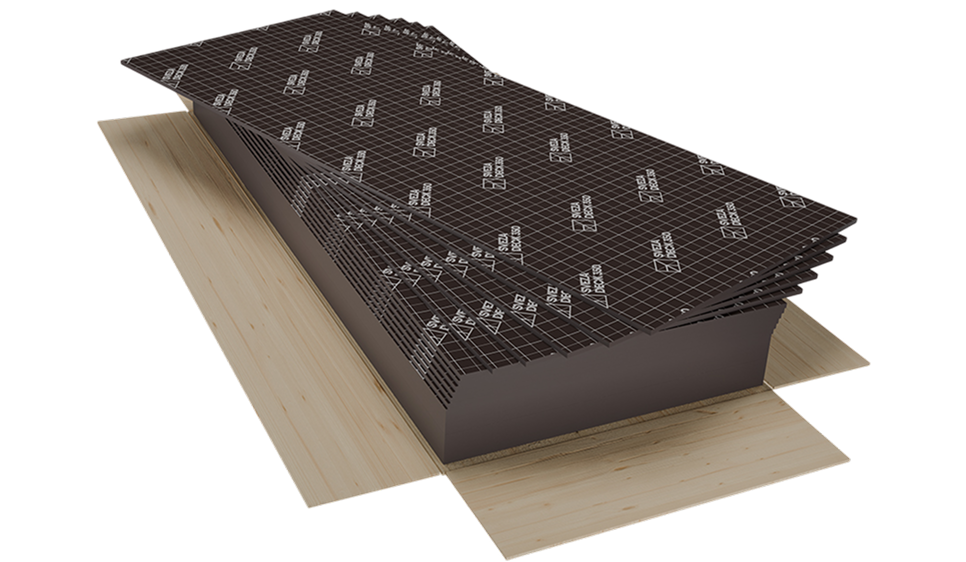

- The possibility of repeated use without loss of quality.

- Reducing installation and disassembly time reduces labor costs.

Wooden formwork:

- Lower initial cost, but high replacement and maintenance costs in the long run.

- A limited number of usage cycles.

4. Quality of concrete structures

Alwood Metal Formwork:

- Ensures high precision and smoothness of the surfaces of concrete structures.

- Minimizes the risk of defects on the concrete surface.

Деревянная опалубка:

- Wooden panels can deform, which leads to irregularities and defects in concrete structures.

- It requires additional treatments to achieve smoothness of the surface.

5. Environmental friendliness

Alwood Metal Formwork:

- The metal is fully recyclable, which reduces the environmental footprint.

- The durability of the product reduces the need for frequent replacement, which also has a positive effect on the environment.

Wooden formwork:

- The production and disposal of wooden formwork can lead to deforestation and an increase in waste.

- It requires regular replacement, which leads to greater consumption of natural resources.

Conclusion

Alwood metal formwork is a modern solution that significantly surpasses traditional wooden systems in a variety of parameters. Durability, cost-effectiveness, ease of use and environmental friendliness make Alwood an attractive choice for construction projects of any scale. The transition to Alwood metal formwork makes it possible to significantly increase the efficiency of construction and improve the quality of final concrete structures.